P-Life Japan Inc., a leader in sustainable plastic technology, has developed a solution to address the growing concern of microplastic pollution. The company’s P-Life technology transforms non-degradable plastics into biodegradable polymers, offering a promising method to mitigate the environmental impact of plastic waste.

P-Life Additive Enhances Natural Plastic Degradation

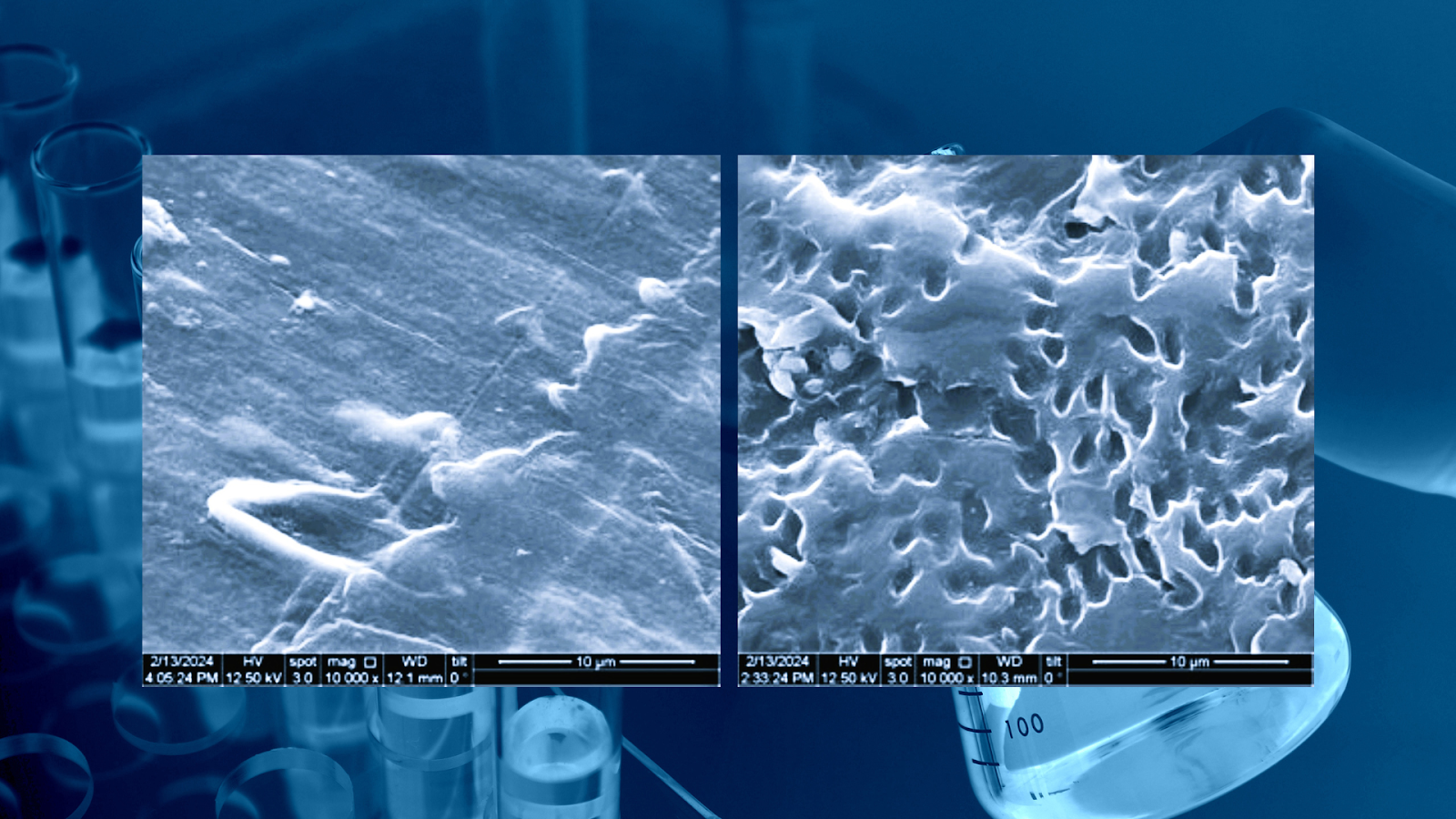

P-Life’s proprietary additive, when incorporated into polyolefin polymers such as polyethylene and polypropylene, accelerates the natural degradation process of plastics. This technology enables manufacturers to customize the lifespan of plastic products, from single-use items that biodegrade within months to more durable goods that maintain their integrity for years before breaking down.

The company’s scientific research, conducted in collaboration with Keio University, has yielded notable breakthroughs. Professor Kenji Miyamoto led the team that discovered a bacterium capable of degrading polypropylene (PP) treated with P-Life additive.

Microbes show promise in breaking down polyolefin plastics. This discovery could reduce microplastic pollution worldwide. New biodegradation methods may address plastic accumulation in the environment.

Recent studies have further validated the efficacy of P-Life’s technology. In November 2024, researchers confirmed that microorganisms decompose persistent plastic straws treated with the P-Life additive, reinforcing this advanced method’s potential to address plastic pollution.

Tackling the Microplastic Crisis at its Source

Microplastics, which are plastic particles smaller than 5 mm, substantially threaten ecosystems and human health. These particles enter the food chain, affect marine organisms, and potentially cause adverse effects in humans. P-Life’s technology breaks down plastics into smaller, non-toxic components that nature absorbs, effectively addressing the microplastic issue at its source.

However, while P-Life’s technology accelerates biodegradation, it does not instantly solve the problem of existing plastic pollution in the environment. Breaking down plastics takes time, and the technology works most effectively when applied to newly manufactured products. This highlights the need for a comprehensive plastic pollution plan with advanced technologies and broader environmental initiatives.

Research Reveals Health Risks Associated with Microplastics

Scientists worldwide continue to worry about microplastics’ impact on human health and ecosystems. Studies have detected microplastics in various human biological samples, including lungs, blood, and breast milk. These particles disrupt marine ecosystems, hinder plant growth, and potentially lead to various health issues in humans.

Recent research has highlighted additional health risks associated with microplastics. A study published in early 2025 found that exposure to microplastics increases the risk of heart attack and stroke in people with heart disease. This finding emphasizes the urgency of addressing microplastic pollution and the potential benefits of technologies like P-Life’s biodegradable plastics.

P-Life’s biodegradable plastics offer a solution that guarantees plastic products degrade naturally after their intended use, eliminating the likelihood of microplastic formation. This method aligns with global efforts to mitigate plastic pollution and its associated health risks.

Nevertheless, this technology represents one part of a broader solution and must be combined with other strategies to address the existing plastic pollution problem comprehensively.

Cost-Effective Integration into Manufacturing Processes

P-Life Japan’s technology has garnered attention for its seamless integration into existing plastic manufacturing processes. The additive requires only a small percentage to be effective, making it an economically viable option for businesses looking to enhance their sustainability profiles.

Consumer demand for eco-friendly products grows alongside regulatory pressures, and P-Life Japan Inc.’s advanced method positions the company at the forefront of the sustainable plastics industry. P-Life Japan Inc. contributes to environmental conservation while creating a path for a more sustainable future in plastic production and use by addressing the critical issue of microplastic pollution.

The potential applications of P-Life Japan’s technology extend beyond consumer goods. Industries such as agriculture, packaging, and construction are exploring ways to incorporate biodegradable plastics into their operations. This widespread adoption could dramatically reduce the long-term environmental impact of plastic use across various sectors.

Overcoming Implementation Barriers and Future Research Directions

While P-Life Japan’s technology offers considerable promise, scaling up production and establishing widespread adoption present ongoing challenges. Educating consumers and industries about the benefits of biodegradable plastics and their proper disposal remains crucial to maximizing the technology’s impact.

Furthermore, ongoing research must fully understand how biodegradable plastics affect various ecosystems long-term and optimize the degradation process in different environmental conditions.

P-Life Japan Inc.’s advanced biodegradable plastic technology is a significant step in combating microplastic pollution. It offers a promising solution for newly manufactured plastics, yet addressing the global plastic pollution crisis demands a multifaceted technique. This incorporates state-of-the-art technologies like P-Life, improved waste management systems, increased recycling efforts, and reduced overall plastic consumption.

P-Life Japan Inc. helps reshape the plastic industry and protect ecosystems worldwide from the pervasive threat of microplastics by offering a solution that balances environmental responsibility with commercial viability. The company’s contributions may be crucial in creating a more sustainable future for plastic use and environmental conservation as research continues and technology advances.